About

Creedx offers volume production, bespoke, prototypes, and short runs, and R & D Projects.

Creedx can provide end-to-end solutions from concept to finished part production, covering detailed design, Mold Design, Mold production, material selection, laminate design, Part manufacturing, and UV clear Coating.

Carbon fiber Parts Manufacturer in India with 16000 Sq.ft plant area.

We design and develop the product in High-Quality Carbon fiber. We specialize in Tooling Design.

Our areas of expertise are Carbon Composites, Carbon fiber Bicycle, Racing Cars in Carbon fiber, Carbon fiber Electric Car, Carbon Fiber Electric Bike, Motorsports in carbon fiber, Composite Air Frame for UAVs , Aerospace, and Defense.

Manufacturing Capabilities

Engineering Support

Engineering Support offers expert consultation and technical solutions to optimize engineering processes, enhance project performance, and address complex challenges effectively. Our experienced team provides tailored assistance, ensuring quality outcomes and driving innovation across various engineering disciplines.

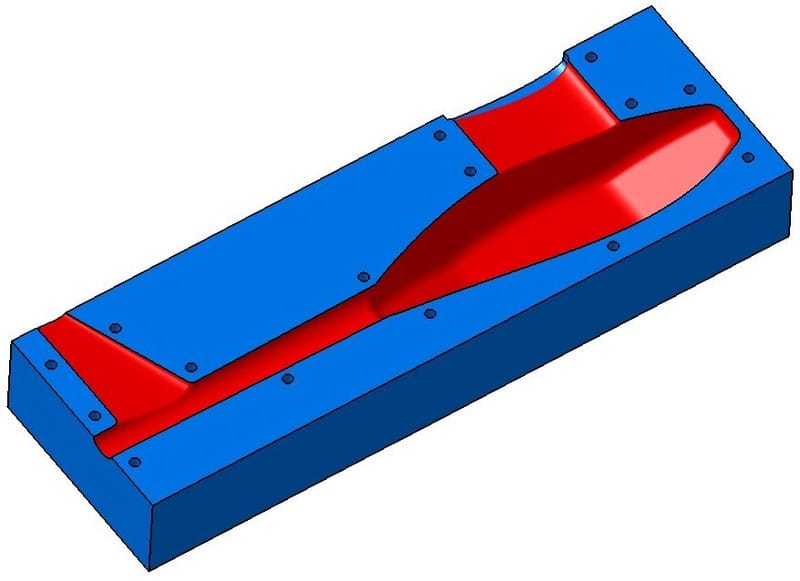

Tooling Design

"Tooling Design services specialize in crafting precise, durable, and efficient tools tailored to meet the specific needs of industries. Leveraging advanced engineering methodologies, we deliver innovative solutions that enhance production capabilities while ensuring cost-effectiveness. Our team collaborates closely with clients to conceptualize and execute tooling that optimizes performance and guarantees long-term reliability, setting the foundation for operational success."

Process Design

We can work with you to freeze the layup schedule, material selection, and ply placement. We will prepare the Layup book to ensure that product configure as per customer requirements.

Freezer / Cold Storage Room

Cold Storage for Prepreg - Prepreg Storing Capacity up to 4000 Sq,Mtr

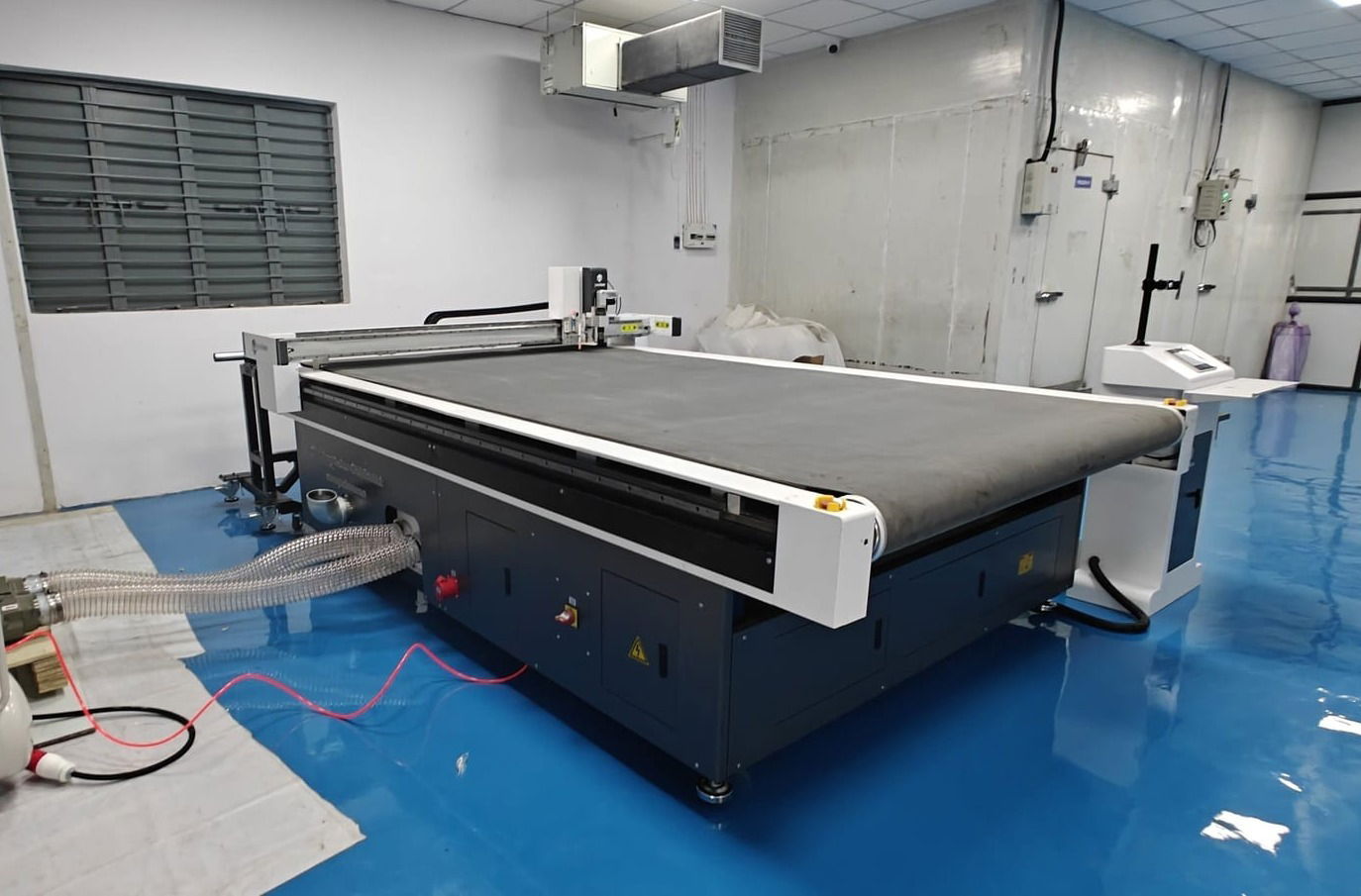

Prepreg Cutting Zone

We have CNC Prepreg cutting machine to cut the Carbon Fiber precisely.

Laminating

We have Clean-Room for lamination, Our laminator has experience with laminate components using Carbon/Glass prepreg.

Oven/Autoclave

Currently, we have 1 Autoclave(1.5mtr-Dia X 4.2mtr-Length), which is good for 200 Deg C with 8 Bar working pressure. Additionally we have one oven (2mtr-Width X 2mtr-Height X 1.7mtr-Depth) and another Oven with 1.2mr x1.2mtrx1.2mtr.

Quality Standard

Quality and Clients expectation are crucial factors in the success of CREDDX. To become the world’s leading company in the manufacture of premium and Luxury carbon fibre components, CREEDX always pushing their limits to highest quality standards. Creedx is proud to hold ISO 9001-2015 ans Aerospace standard AS 9100 international quality certifications.

Trimming & Finishing

We have Trimming and finishing activities, we have a small size of paint booth for UV clear coat to carbon composite parts. We order big size Automotive paint booth and will be operational by Feb-2025

Quality Control

We have a surface Table, Vernier Calipers, thickness Gauge. We develop one vendor for FARO scan and CMM for our higher precision Jobs.

New Product Development

We are researching on new product for Medical industries and Textile industries at this moment and expecting to have this product inmarket by 2024.

UAVs Development

- We provide end to end solution for all types of UAV's Carbon Composite Air frame Development.

- Our expertise will help to design the shape/profiles of composite Air frame because flow of fibers and composite Layup is the key factor to achieved desire strength with lowest weight and we provide end to end solution.

- We support for Prototypes developments.

- We help to decide the the right carbon fiber for your UAVs.

- We allot the dedicated team and resources for the exclusive Composites Air frames production. so our customer don't need to worry about their composite parts and we provide door delivery based on their assembly schedule.

- We take full responsibilities of Composite Air frame.

Contact

- Creedx Composites Private Limited , Plot No: C, 20/8, Rd Number 15, Hoziwala Industrial Estate, Sachin, Surat, Gujarat 394235, India

- 394235

If you like to develop product in carbon Fiber send us your details and we will come-up with the solution.

Terms and Condition

F.A.Q

Why Carbon Fiber number one choice for Automotive, Aerospace, racing, Motorsports ?

- Carbon Fiber is stronger than other materials like a steel and its made up with fibers and resins which contribute to their strength. Fibers carry the load, while resins distribute the weight throughout the composite part.

- 42% lighter than an aluminum and 5 times lighter than a steel.

- Highly resistance to weather and harsh chemicals which makes them a good choice for applications that face constant exposure to salt water, toxic chemicals, temperature fluctuations and severe conditions.

- Highly durable and flexible to achieve any types of complex shape

What services do you offer?

- Tooling Design

- Process Design (Carbon Lay-up, Material selection)

- Aluminum Mold manufacturing.

- UV Coating

- Composite to Metal Bonding.

- Composites part production (Prototypes/small quantity to Large Numbers)

Standard Timeline to develop new product?

- Our product Development stages and approximate timelines are as below:

- Product Review : 1-2 Days

- Tooling Design : 1-5 Days based on complexity

- Tooling production : 15-30 Days

- Prototypes production : 2-3 Days

- Part production : 1-2days

what is the cost of Carbon fiber parts?

- There are a different types of Carbon Fiber available in the market based upon the applications.

- You can not derive the cost from its weight, Cost is calculated based on Fiber types & Manufacturing process we used.

- Difficult to say the cost of the part without study the component thoroughly.