Manufacturing Capabilities

Engineering Support

Engineering Support offers expert consultation and technical solutions to optimize engineering processes, enhance project performance, and address complex challenges effectively. Our experienced team provides tailored assistance, ensuring quality outcomes and driving innovation across various engineering disciplines.

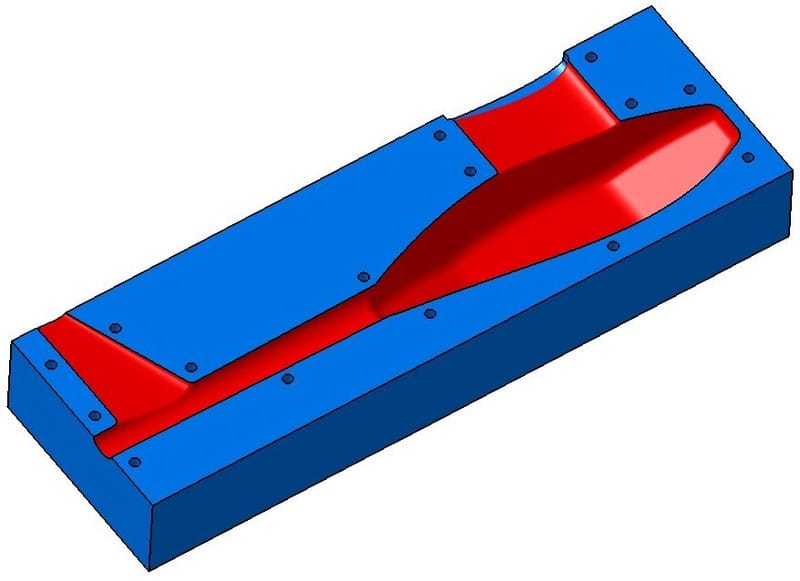

Tooling Design

"Tooling Design services specialize in crafting precise, durable, and efficient tools tailored to meet the specific needs of industries. Leveraging advanced engineering methodologies, we deliver innovative solutions that enhance production capabilities while ensuring cost-effectiveness. Our team collaborates closely with clients to conceptualize and execute tooling that optimizes performance and guarantees long-term reliability, setting the foundation for operational success."

Process Design

We can work with you to freeze the layup schedule, material selection, and ply placement. We will prepare the Layup book to ensure that product configure as per customer requirements.

Freezer / Cold Storage Room

Cold Storage for Prepreg - Prepreg Storing Capacity up to 4000 Sq,Mtr

Prepreg Cutting Zone

We have CNC Prepreg cutting machine to cut the Carbon Fiber precisely.

Laminating

We have Clean-Room for lamination, Our laminator has experience with laminate components using Carbon/Glass prepreg.

Oven/Autoclave

Currently, we have 1 Autoclave(1.5mtr-Dia X 4.2mtr-Length), which is good for 200 Deg C with 8 Bar working pressure. Additionally we have one oven (2mtr-Width X 2mtr-Height X 1.7mtr-Depth) and another Oven with 1.2mr x1.2mtrx1.2mtr.

Quality Standard

Quality and Clients expectation are crucial factors in the success of CREDDX. To become the world’s leading company in the manufacture of premium and Luxury carbon fibre components, CREEDX always pushing their limits to highest quality standards. Creedx is proud to hold ISO 9001-2015 ans Aerospace standard AS 9100 international quality certifications.

Trimming & Finishing

We have Trimming and finishing activities, we have a small size of paint booth for UV clear coat to carbon composite parts. We order big size Automotive paint booth and will be operational by Feb-2025

Quality Control

We have a surface Table, Vernier Calipers, thickness Gauge. We develop one vendor for FARO scan and CMM for our higher precision Jobs.

New Product Development

We are researching on new product for Medical industries and Textile industries at this moment and expecting to have this product inmarket by 2024.